Blog, Flat-Free Tires

Flat-Free Tires vs. Traditional Wheelbarrow Tires: What’s Best for You?

You’ve probably experienced it: you're hauling mulch across your garden, when you roll over some sharp rocks and you hear the awful hiss of air escaping from your now-punctured tires. Now you have this wheelbarrow full of mulch that you’ll have to roll somewhere with that flat tire. You’ve now wasted the time you’ve set aside for your gardening project, and you have to use that time to run out to the hardware store to buy a replacement. You think, "There has to be a better way."

Good news—there is! Flat-free tires offer a durable alternative to traditional air-filled tires. But are they right for your wheelbarrow?

At Lapp Wagons, we’ve been in the business of making your wheelbarrows and wagons work harder for you so that you can move your loads with confidence. We’re so particular about our products that we even produce our wheels, ensuring you get the best.

Whether it’s hauling old roofing shingles at the job site, mulch for the garden, or giving the kids a ride, you can count on Lapp Wheels for a smooth, easy ride that lasts for years and years.

Ready to find out if flat-free is right for you? Let’s take this blog for a spin!

What Is a Flat-Free Tire and How Does It Work?

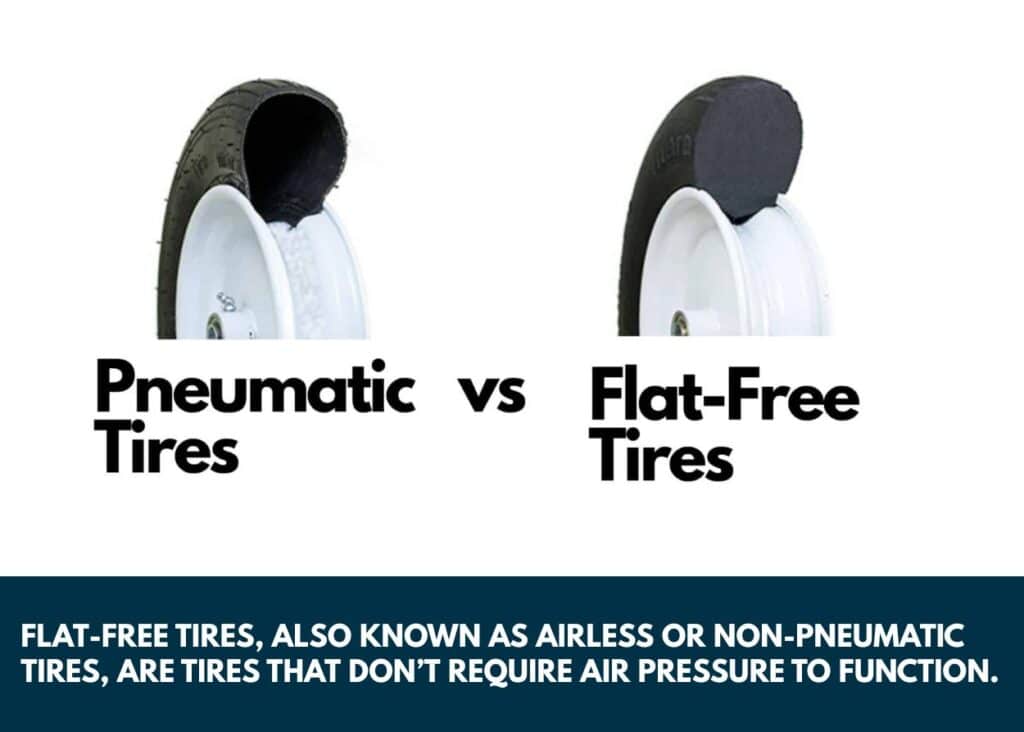

Not to be confused with run-flat tires on cars, flat-free tires, also known as airless or non-pneumatic tires, are tires that don’t require air pressure to function.

Think of them as solid yet slightly flexible cushions, mimicking traditional tires but eliminating the risk of punctures. With flat-free tires, they never need inflating and won’t unexpectedly deflate, even when rolling over sharp objects.

Flat-free tires aren’t new. An inventor named J.V. Martin filed a patent for the first airless tire in 1938. However, it was commercially unsuccessful due to its then-current inability to keep up with the rapidly developing pace of faster cars, as well as the automotive industry's reluctance to adopt new tire technologies when current, cheaper pneumatic tires already worked so well. A mere 32 years later, however, a significantly advanced version of the airless tire proved its worth in the harsh lunar environment, with the Apollo Lunar Roving Vehicle. Flash forward to today, and the major tire companies are researching the next generation of airless tires for future expeditions to the moon and beyond, as well as for applications a little closer to Earth.

While high-tech tires aren’t necessary for wheelbarrows, today’s flat-free tires are a far cry from the carved wooden wheels of the first wheelbarrows. Let’s take a look at the pros and cons of modern airless tires:

Pros of Flat-Free Tires

Many homeowners and landscapers swear by flat-free tires. Their many advantages get their users on a roll:

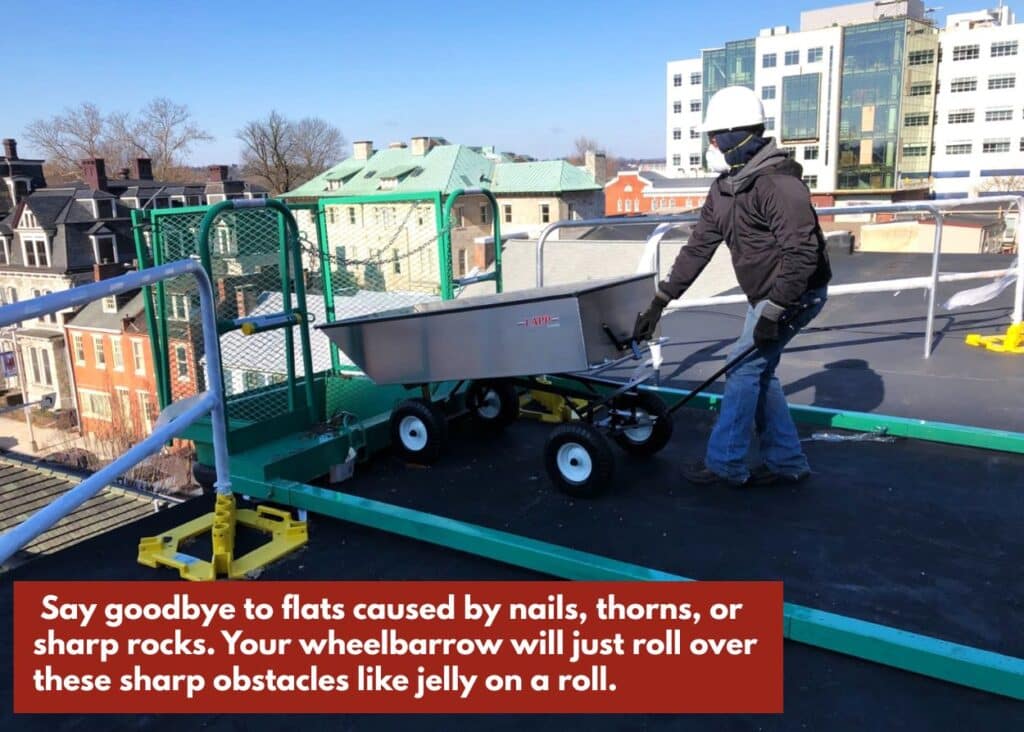

- No punctures: Working in a construction zone or thorny brush? No problem! Say goodbye to flats caused by nails, thorns, or sharp rocks. Your wheelbarrow will just roll over these sharp obstacles like jelly on a roll.

- Low maintenance: Forget constantly checking and adjusting air pressure—once a set of flat-free tires is installed, you can practically forget about it. You could say that with flat-free tires, there’s no pressure to keep checking the tires.

- Longer lifespan: Built to withstand tough conditions, polyurethane tires typically outlast traditional tires, providing many years of reliable performance and service.

- Convenience: No more emergency trips to the store for repairs or replacements. Your wheelbarrow is always ready when you are.

Cons to Consider

Despite their advantages, flat-free tires aren’t perfect. Here are some situations where using airless tires might fall flat:

- Heavier weight: The solid construction of flat-free tires makes them slightly heavier, meaning you may need more muscle, especially when handling inclines or heavy loads. That’s because heavier tires mean increased rolling resistance, meaning it takes more energy to get the wheel rolling and keep spinning.

- Less shock absorption: Unlike air-filled tires, they provide less cushioning. If your landscaping or gardening involves rough terrain or heavy, frequent loads, you may feel more vibration and bumps, which can get unpleasant after prolonged use. Cushioned gloves and wheelbarrow handles can help absorb some of that vibration.

- Cost: Upfront, flat-free tires may cost more than pneumatic tires, although their durability and low maintenance often offset this initial expense.

How to Check Compatibility

So you’ve decided to switch to flat-free tires. Before you upgrade, ensure compatibility:

- Measure your existing tire: Confirm the diameter, width, and hub length to match the new tire. Most wheelbarrow tires are 13” and 16” diameter wheels, with 6” or 8” rims. If you’d like to learn more about determining wheelbarrow tire sizes, check out this blog.

- Axle and bearing size: Check that the axle and bearing specifications match your wheelbarrow’s existing setup. Bearings are typically ⅝” diameter for small wheelbarrows, and ¾” for large wheelbarrows, while standard wheelbarrow axle sizes are ¾” diameter and 1” diameter for the larger ones.

- Weight capacity: Always confirm that the maximum load rating of the flat-free tire aligns with your wheelbarrow's intended use. Most tire resellers display the load rating of each tire on their website, and reputable businesses will be available to answer your questions.

Installation Tips and Recommended Uses

Installing flat-free tires is easy and usually takes just a few minutes, using the same tools you would use to change any other wheelbarrow tire:

- Remove the Old Wheel:

- Loosen and remove the bolts securing the wheelbarrow axle to the frame.

- Carefully remove the wheel from the axle.

- Clean the mounting points of dirt and debris, and add some grease to the mounting points to make the tire easier to install and to remove.

- Prepare the Flat-Free Wheel:

- If you’re installing a universal-fit tire, you may need to add spacers and bushings to the axle, which are usually included with the tire.

- Attach the Flat-Free Wheel:

- Slide the new flat-free wheel onto the axle.

- Ensure the axle is securely attached to the wheelbarrow frame with bolts and washers.

- Tighten and Secure:

- Tighten the bolts securing the axle to the frame.

- Double-check that the wheel is securely attached and that there are no gaps or movement.

Flat-free tires will work on just about any place a conventional pneumatic tire would work, but they shine in these scenarios:

- Gardening and landscaping: Great for routine yard work, where encountering sharp sticks, stones, or debris is common.

- Construction sites: Ideal locations where nails, screws, and sharp materials are regularly used, and even found on the ground, leading to flat tires.

- Commercial applications: Businesses benefit from consistent reliability and reduced downtime.

- Residential DIY projects: Convenient for homeowners who prefer low maintenance.

Are Flat-Free Tires Eco-Friendly?

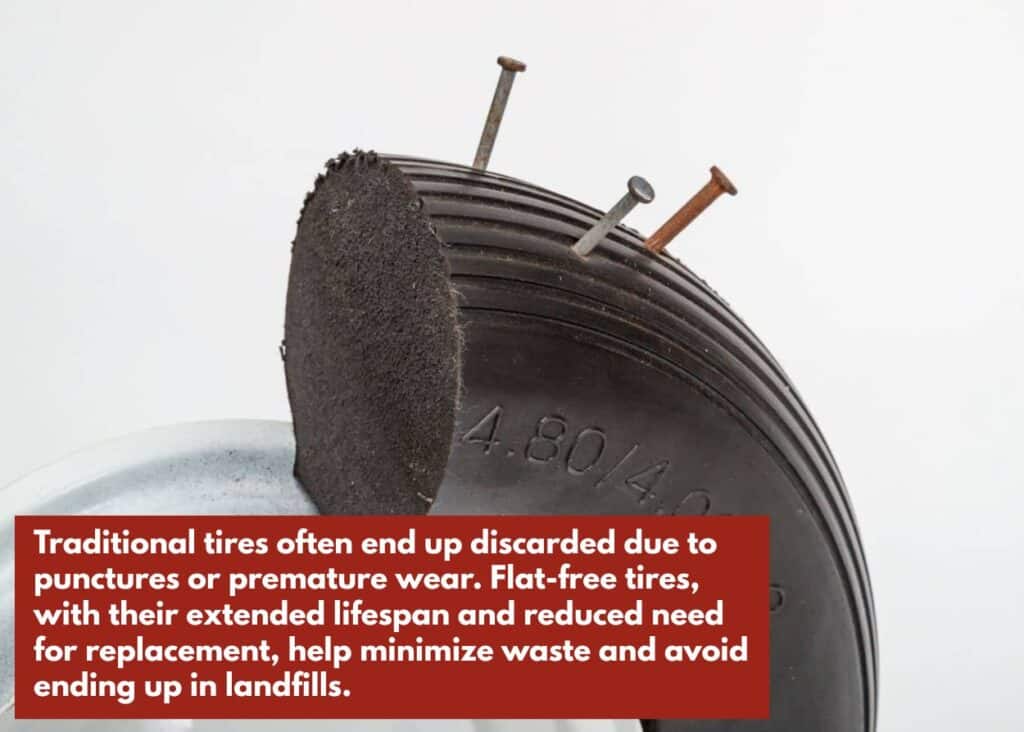

Flat-free tires can be more environmentally friendly in the long term. Traditional tires often end up discarded due to punctures or premature wear. Flat-free tires, with their extended lifespan and reduced need for replacement, help minimize waste and avoid ending up in landfills.

Additionally, less frequent replacement means fewer resources used in manufacturing and distribution.

Are Flat-Free Tires Worth the Investment?

When deciding whether flat-free tires are worth it, consider the bigger picture. Yes, the upfront cost is higher, but if time is money, consider the savings on maintenance, replacements, and time that can quickly offset the initial investment. If you regularly deal with challenging terrains, replace tires that your terrain has ripped up, or need consistent performance without downtime, then flat-free tires easily justify their cost, providing peace of mind and convenience.

Conclusion

To summarize, regular pneumatic tires have air and can be punctured. Flat-free tires will never go flat, take a lot of punishment, and last longer than regular tires.

On the other hand, flat-free tires are more expensive. You’d also want to factor in the reduced comfort level as it doesn’t handle bumps well, and the heavier tires require more muscle to get rolling. The higher price can be offset by the fact that you’ll replace the tire far less often and spend little to no time on maintenance or repairs, leaving you more time to focus on your work.

The final factor is quality, and with any product, the quality of the product translates to the experience you’ll have. You’ll have no better experience using tires from Lapp Wagons.

Manufactured on an Amish farm in Ephrata, PA, our wagons, tricycles, and wheels have embodied craftsmanship and quality since 1962. When you choose Lapp Wagon, you're getting:

- Quality Construction: Each product reflects the meticulous craftsmanship and robust materials typical of Amish workmanship.

- Proven Reliability: Designed for demanding uses, ensuring they perform reliably under heavy use and tough conditions.

- Local and Trusted: We proudly stand behind every tire we produce, offering friendly customer service and support, along with a limited 2-year warranty.

Ready to say goodbye to frustrating flats? Choose the durability and ease of flat-free tires from Lapp Wagons and keep your projects rolling smoothly.

Contact us today. Your wheelbarrow—and your back—will thank you!